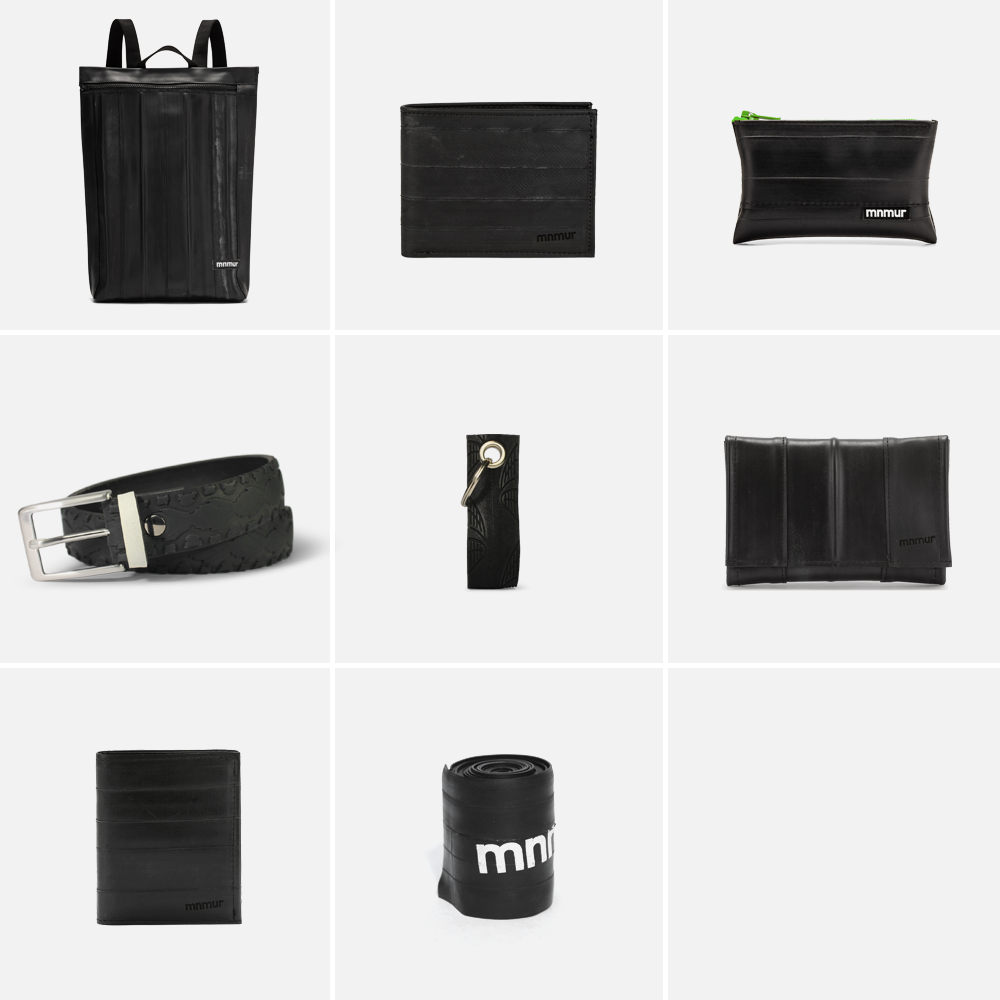

HOW WE MAKE PRODUCTS

We design and create sustainable products.

Our collection is made using recycled bicycle inner tubes and tires.

We are committed to creating durable and functional products, inspired by simplicity and essentiality. With passion and dedication, we constantly work to enrich our collection, crafting each item by hand with great care and attention to detail.

Upcycling is a particular way of recycling.

The creative approach in this process reveals the hidden potential behind the material and opens the way to a new aesthetic.

What is considered waste material, deemed worthless, can instead be used to create a new, marketable product, with great benefits for the environment.

For us, bicycle inner tubes and tires are a fascinating and special material.

These materials were designed to withstand harsh conditions of use, and their technical characteristics are excellent compared to traditional industrial textile materials.

Durability, waterproofness, strength, and lightness are ideal properties for designing bags and accessories for everyday use.

From an aesthetic point of view, inner tubes offer a wide variety of textures and details that make each product unique. Additionally, there is the rare beauty that only time can give to materials, such as shades, scratches, and signs of wear.

Details make the difference.

The writings and numbers on bicycle inner tubes are a source of inspiration.These elements, added by the manufacturing companies, become an integral part of our design and aesthetic research.Fonts and colors, numbers and text are the elements we look for to express our creativity and add value to the product.

The production process.

For us, handmade means a combination of values and experiences. A bag, a wallet, or a belt are not just simple objects; they are the result of an idea taking shape through imagination, creation, and passion.

We are completely self-taught in craftsmanship; our educational background is in the arts and graphic design. This project initially started as a hobby—we simply wanted to try creating something while having fun. The first sales and the appreciation from the public encouraged us to keep going, and over the years, we've made great progress.

Designing is the most beautiful part of our work, and the real challenge is creating something from scratch.

Urban culture and the surrounding environment provide our main source of inspiration. When we think of a new product, we want to create something functional, durable, and attractive. We love simplicity and minimalism.

We have two different approaches: one is more analytical and experimental, while the other is more intuitive and direct. The first method combines research, analysis, and thorough testing, allowing us to verify the feasibility of ideas, often resulting in random outcomes that sometimes lead to great solutions. The second, which we would call a stream of consciousness, is the free expression of an idea, without specific rules or order. The development of new products can take a lot of time, sometimes even years. We are constantly looking to improve.

Recovering waste material

Very often, when bicycle inner tubes get punctured, they are not repaired. As a result, bike shops accumulate a lot of waste material that then has to be disposed of. Recovering it means preventing it from ending up in a landfill.

There are different types of inner tubes and tires; not everything can be used to make products, and the material must be carefully selected before being used.